Machine Recycling Discussion and Moderated Newsgroup > Separate Parts

> Electrical Parts

> North

> Used

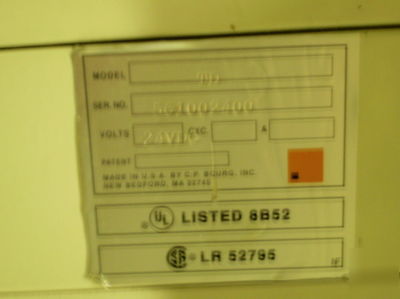

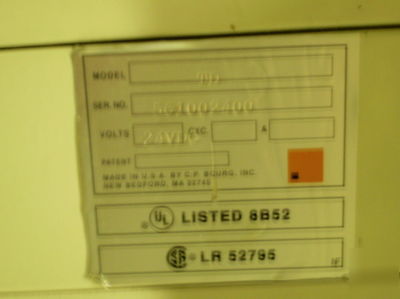

> Bourg model ae-16 w/td receding stacker

Bourg model ae-16 w/td receding stacker

CP Bourg made a huge leap when they redesigned the Bourg horizontal collator and introduced the AE - Electronic collator. The AE Bourg systems are still widely used. They are fast and operator freindly. Most of all they are not excessive with sensors and logics like the new collators being introduced today. The AE system has just what it needs and assumes the operator has some machinery operating skills. In other words it is not a copier. It is a manufacturing machne. Now for the AE Advantages.

1) Electronic progammed logic. By utilizing a simple trigger logic the AE fires each bin with precision. The timing beteeen bins is exact. This allows the stream of collated sheets to deliver more consitently than before. The A uses mechanical switches activated by a drum with cams. No two switches are ever going to fire at the same time.

2) By using an encoder to regulate the firing pulses the AE will always have control of bin pulses. Also by using an encoder Bourg was able to add a spacing feature. Spacing is exclusively an AE feature. It allows the operator to increase the space between each sheet in the stream. This helps when collating large sets like 22 sheets and higher. It also helps with coated papers and reduces static problems.

3) The CPU is split into 4 segments allowing the collator to be split into 4 programs. If you have a 10 bin you can run an 5 x 5 split run or 3x3x3 or 2x2x2x2 This will allow you to load a 3 signature booket in 3 positions thereby reducing loading tme and increasing production. The CPU automatically allows enough time between sets for the stitch, Fold, Trim to cycle.

4) AE systems also provide Short Cycle. What this does is elecronically reduce the size of the collator. If you have a 10 bin all 10 bins fire on each cycle whether you are using 10 bins or just 5 bins. By using the short cycle feature you can eliminate, for example, all but 5 bins. This increases production by eliminating the time it takes to fire the remaining bins. This can increase production to 3500 cycles per hour.

5) AE systems provide an advance CFS control board. This system is linked to an infrared sensor at the end and allows the accurate timing of the stitcher and stacker for improved performance. This circuit also provides timing adjustments for back jogger, side jogger and stitch pulse.

6) AE systems also provide advanced infrared doubles detection. This system is unique in the industry. No other collater before or since allows the operatoor to calibrate each infrared sensor on each bin. On all other collators equipped with doubles detection the bins calibrate automatically which can be problematic depending on ambient light at the collators location. Bright sunlight, Incandescent lighting, flourescent lighting. Also the doubles detect can be turned off. Another exclusive feature of the Bourg AE.

7) AE collators also provide DC drive controls instead of an AC motor with variable speed pully drive. This allows for smoother operation improving set collating and delivery. Also allows operator to quickly change speeds to accomodate a wide variety of stocks, the operator can change speed from the delivery end of the collator.

3 HOWE DRIVE, UNIT 2 AMHERST, NH 03031

PH:(***)-880-1437 F: (***)-880-1436