Machine Recycling Discussion and Moderated Newsgroup > Full Machines

> Incomplete Machines

> North

> Used

> 2007 campbell pioneer horizontal wrapper

2007 campbell pioneer horizontal wrapper

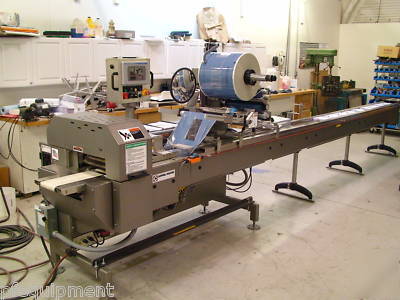

2007 Campbell Pioneer Horizontal Wrapper

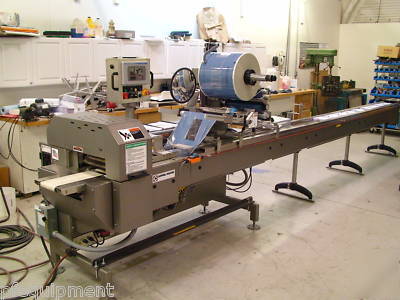

Nice 2007 model Campbell Pioneer Horizontal Wrapper available! This is a 3-Axis Servo Horizontal Wrapping Machine. Speeds of up to 250 PPM depending on product being run.

Pioneer Horizontal Flow Wrapper Applications Include:

Sports Cards, Phone Cards, Greeting Cards/Envelopes, Wrapping Paper, Cosmetic Samples, Fire Logs, Dog Bones, Carpet Molding, Eye Droppers, Crackers, Toaster Pastries (Stacked), Fruit Pies, Fortune Cookies, Buns, Moon Pies, Cookies, Chocolate Bars, Breakfast Bars, Individual Slices of Cheese, Chunk Cheese, Waffles, Pancakes, Popcorn Balls, School Lunches, Sandwiches, Burgers, Gum, Fish Sticks, Chicken, Coffee Filters, Pie Crusts (In Tins), Peppermint Sticks, Chocolate Balls.

Type: 3-Axis Servo Horizontal Wrapping Machine

Servo Controlled Film Registration

Speed: 250 ppm (speed capability based on product size and pkg material used.)

Quick-Release Film Former set up for Package Size*: 9 L x 6-1/2 W x 3/4 H

Width: ............................. 6 1/2" (165mm)

Height: ............................ 2-1/2" w/4-5/8", 3-1/4" w/5-l/2, 4-1/4" w/6-1/2" head

Girth: .............................. 16" (406mm)

Type of Wrapping Material: Polypropylene, Cellophane, Poly-coated Paper, Laminates, High Density Polyethylene

Type of Seal: Fin Seal, Crimped Extended Ends

* Left hand machine configurations with the product flowing from right to left as the operator faces the control panel. Rugged steel frame construction and timing belt drive components provide for machine durability and smooth maintenance-free operation. Sanitary cantilevered design allows debris to fall away from internal drive components.

* Standard servo driven infeed conveyor provides for 12' 6" of clear feeding space including standard pusher chain with declining lugs and appropriate pushers. Stainless steel conveyor deck with adjustable lipped side guides. All parts in contact with the products are of stainless steel or FDA-approved material. Product hold down rails provided prior to entrance to former.

* High product detector will stop the machine when a product exceeding height specifications is detected.

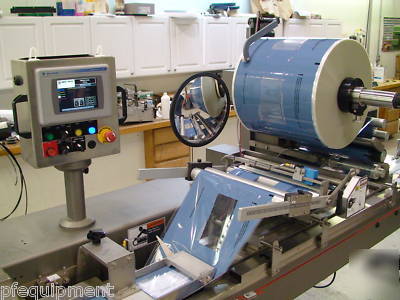

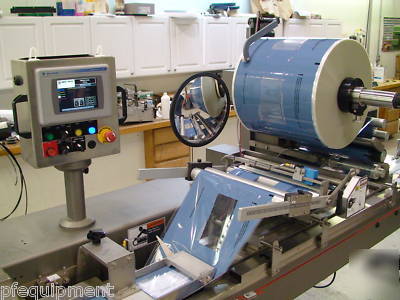

* Single roll cantilevered backstand with automatic core lock and independent screw adjustment for roll centering accommodates quick roll changes. Maximum roll width 16 inches; maximum roll diameter 16 inches; 3 inch diameter cores.

* Powered film drive roll provides for additional film tension and position control.

* Adjustable "s" wrap film rolls for precise setting of film entry angle to forming box.

* Slack web detector monitors film tension and will automatically shut wrapper off in the event of a film break.

* One (1) quick release, fixed position, stainless steel forming box custom designed to accurately form the film around 9 L x 6-1/2 W x 3/4 H product.

* One set of cold fin wheels and one set of hot fin wheels are used to make the longitudinal seal. Cutout top plates and insulated fin wheels for tighter package. Fin wheel assemblies are servo driven and cantable for precise film control. Automatic release of heated fin wheels prevents film from burning during machine stops and manual release of cold fin wheels keep film positioned during stops. Brushless sealed contacts are used to transfer heater power and thermocouple signals. Cantilevered tube forming section is of sanitary design allowing debris to fall away from internal drive components. Standard 1/2" wide knurled fin pattern provided.

* Servo controlled registration system, via fin wheel servo drive, provides precise film print positioning.

* Servo-driven one-up cutting head assembly with standard 3/8" wide threaded style crimp pattern, shimable style diagonal-cut knives. Shimable diagonal knife minimizes cutting pressures and extends knife life. Special angled crimpers for optimum shorter package repeat.

* Heaters are mounted in crimpers providing a uniform temperature pattern. Brushless sealed contacts are used to transfer power and thermocouple signals.

* Servo drive to cutting head adjusts crimper speed to match film speed and is easily adjusted via PanelView entry when changing product lengths.

* Automatic position stop with crimpers in open position prevents film from burning.

* Electronic torque sensing for cutting head drive protection.

* Standard straight-out belt discharge conveyor extends approximately 12" past machine frame.

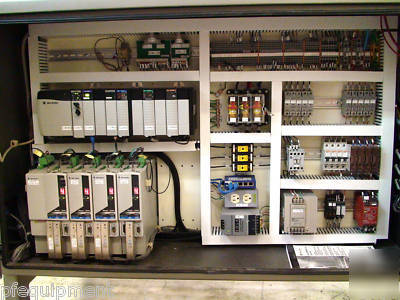

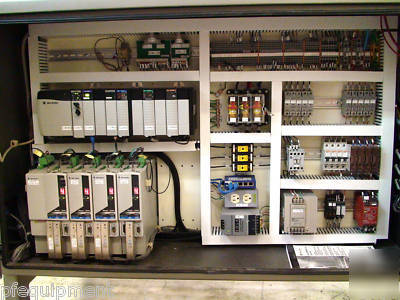

* Allen Bradley drive and control package to be provided including:

* PanelView Plus 700 color touchscreen operator interface with Ethernet communications

* ControlLogix 5000 Series PLC control

* AB Kinetix 6000 servo amplifiers

* PLC and amplifiers to communicate via SERCOS

* Menu-driven set-up procedure

* Two level access, one secured, one unsecured

* Product per minute display, totalizer display, production records and fault display included

* Forty (40) record set-up storage recipe retrieval

* CE 1 UL touchsafe components

* Quick disconnect sensors and actuators

* Campbell Wrapper No Homing feature for most E-stop and guard opening conditions

* Internal control of three temperatures with access through PanelView for control of heated fin sealer assembly, upper crimper shaft and lower crimper shaft.

* Delayed start with audible alarm provides notice that machine will be starting while in continuous running mode.

* Standard utility specs: Electrical-208 volt, 3 phase, 60 Hz., 40 Amp, Air-80 PSIG.

* Steel Tuff-316 painted exterior including guards and cabinets.

* Standard safety features including guarding, guard safety switches, E-stop button with E-stop relay and machine reset button, safety cable stop on infeed conveyor and lockable main power disconnect.

SPECIFICATIONS (Approximate)

(Approximate metric units in parenthesis)

Ergonomic cantilevered frame design

Allen-Bradley drive and control package including:

- PanelView color touchscreen operator interface with Ethernet communications

- Control Logix 5000 Series PLC Control

- PLC and amplifiers to communicate via SERCOS

- Product per minute display, totalizer display, production records and fault display

- Password for different level of access

Length: .................................... 13' 2" (4013mm)

Width: ...................................... 3' (914mm)

Height: ..................................... 5' 8" (1727mm)

Weight: .................................... 1800 lbs. (approx.)

Infeed Elevation: ...................... 34"-36" (864mm-914mm)

Infeed Clear Feeding Space: .... 12' 6" (3810mm)

Maximum Cycle Speed: ........... 250 cpm (determined by application)

Self-Centering Parent Film Roll:

Maximum Width: ........... 16" (406mm)

MaximumDiameter: ....... 16" (406nun)

Core Diameter: ............... 3" (76mm)

Fin Wheels: ............................. One set each Hot/Cold with Auto Release; wide knurled fin pattern.

Cutting Head: .......................... 6-1/2"(165mm); with Standard 3/8 wide threaded style crimp pattern.

Cutting Head Options avail:.... 4-5/8",5-112"(117mm, 140mm)

Discharge Conveyor: ............... 12 past machine frame x 6" wide (152mm wide)

Width: ............................. 6 1/2" (165mm)

Height: ............................ 2-1/2" w/4-5/8", 3-1/4" w/5-l/2, 4-1/4" w/6-1/2" head

Girth: .............................. 16" (406mm)

Electrical Requirements: ........... 208V, 60 Hz, 3 Phase, 40A

Motor (Main): ........................... brushless Servo

Motor (Film Feed): .................... brushless Servo

Motor (Sealing Jaws): ............... brushless Servo

Air Requirement: ....................... 80 PSIG, consumption <1 cfm

Out of position no-cut feature

No product no package feature

Right or left hand construction

Extra length of receiving conveyor (pusher or platform)

Multi-flight receiving chain

High product or slack web detector

Code daters and ink j et units

Multiple crimper cutting head

Header style crimpers with hole punch

208, 480 and other volt supplies

Additional operator interface options

Maintenance call light and switch

Automatic or semi-automatic feeding solutions

* Please e-mail us your phone number for the freight company in case they need to contact you.

* We will make every attempt to answer emails promptly.

* Please contact us with any questions you may have before you purchase any item.

* You are purchasing the item(s) as photographed.

* Many of our store items are eligible for you to make us an offer. Click on the "Make Offer" button (if available) to send us your offer on the item you are interested in purchasing. Please note that our regular business hours are Monday through Friday, except Holidays.