Machine Recycling Discussion and Moderated Newsgroup > Full Machines

> Complete Machines

> Woodwworking

> South

> Used

> Nsk e 800Z complete set cnc lathe machine tool spindles

Nsk e 800Z complete set cnc lathe machine tool spindles

NC / CNC LATHE & AUTOMATION SOLUTIONS E800Z SERIES ELECTRIC SYSTEM COMPLETE SET

Outside Diameter 1.18" ( 25 mm)

High-speed brushless motor is employed. Motor speed : 20,000~80,000 min-1(rpm)

Auto or Manual Control Modes.

Can be installed on a Special-Purpose Machine, NC Lathe, Robot, etc.

Motor speed is displayed accurately on the front panel.

-NE147-800 Control Unit; Power Cord Air Hose with filter (K-251) : 6 mm x 6 ft Reducer Clamp Core Fuse

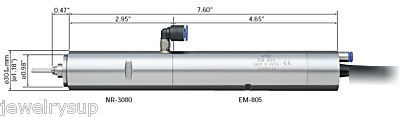

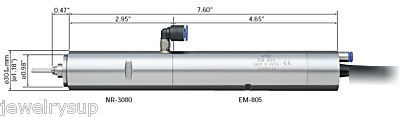

-EM-805 Brushless Motor; Cord with Quick Disconnect Air Coolant Hose : 13 ft Reducer Wrench (22 x 27) : 1 pc.

-NR-3080 Spindle; Collet 1/8" (CHF-3.175) Air Hose : 4 mm x 13ft Wrench (7 x 5.1), (22 x 27) : 1 pc. each.

NE147-800 Control Unit Specifications

Power Source : AC 115V/230V (switchable type) 50-60 Hz

Dimensions : W8.27" x D11.42" x H3.82"

Overload Protection System ensures safe operation and stops the motor in case of overload.

LED overload warning. If the system is operated in overload for more than 15 seconds the overload protection system will activate and interrupt power to the motor. (The stop signal can be output outside)

500 min-1(rpm) operation for centering. ([5] Motor Speed Control Select Switch)"

EM805 Brushless Motor Specifications

Motor Speed 20,000~80,000 min-1(rpm) Brushless Motor [20,000 min-1(rpm) or less for centering rotation.]

Cord with Quick Disconnect Length 13 ft

Air Coolant Hose Length 13 ft

Weight 1 lb. 13.74 oz. (w/cord)

NR-3080 Spindle Specifications

This spindle is ideal for small diameter milling, drilling, slitting, chamfering, grinding, etc.

Air borne oil mist lubrication is required during operation, due tothe extremely high-speed rotation.

Allowable Motor Speed 80,000 min-1(rpm)

Standard Size Collet (CHF-3.175) 1/8"

Oil Mist Air Consumption 1.94CFM/min (64PSI)

High-Performance Electric Circuit

Motor/Spindle is stopped safety, Error LED is lit, and Error Signal is output to external when there is something wrong with the motor/spindle, or any failure is detected. ex.) Overheat/Overload operation, Air shortage

External Input-Output Connector

Motor/Spindle can be controlled and monitored by external input-output connector. Control : Start/Stop, Motor Speed Control, FWD./REV. Rotation and etc. Monitor : While Rotating, Rotation Pulse, Unit Power Source Detection, AUTO Mode, Motor Speed Voltage and etc.

[3] Motor Speed Display (SPEED)

[5] Motor Speed Control Select Switch

[6] Control Switch (AUTO/MANUAL)

[7] Motor Rotation Direction Control Switch (FWD./REV.)

The E Series motor is a brushless DC motor utilizing hall elements, the rotor unit is a rare-earth magnet, motor develops 300W.

Excellent durability and high reliability were obtained using a high-speed brushless motor, which eliminated the nuisance of brush replacement and maintenance. Motor speed control is a wide range : 20,000~80,000 min-1(rpm) {0~20,000 min-1(rpm) : For centering}

Brushless motor has no carbon brushes or commutator, minimizing wear and resulting in a long service life. Due to the brushless construction, electrical interference and other noises are minimized.

Excellent Durability by air-cooling system

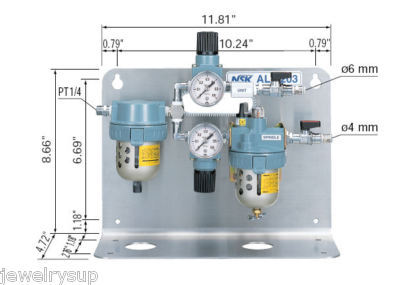

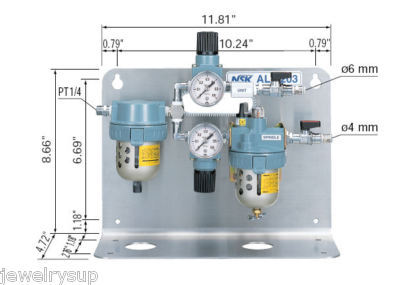

Air-cooled motor uses a small volume of air (1.0CFM) to prevent heat buildup and allow long continuous operation. Clean dry air is required to cool the motor and protect the spindle from contaminants. Use a filter, regulator and lubricator.

(Proper air pressure 28~71PSI) (Use Air Line Kit AL-0203)

Ultra-precision ceramic bearings is installed with NR-3080 to withstand high-speed up to 80,000 min-1(rpm) . Atomized oil is needed for NR-3080 while rotating. Air bearing mechanism is built in NRA-5080 to speed up to 80,000 min-1(rpm) .

Safety Relay is installed as Standard Equipment

The safety relay utilizes normally open contacts. The emergency stop signal lines must be supplied with power to hold the safety relay contacts closed and allow the control unit to supply power to the motor. Any system errors, trouble with the machining center or the connections between the E800Z Series control unit and the machining center's controller will cause the relay contacts to open and the E800Z Series motor or stop.

The control unit constantly monitors the motor conditions, and will cut power in the event of a motor overload. The system will alert the operator by an error code output.

Dual Voltage 115V/230V AC Power Source

The control unit is compatible with 115V-230V main supply voltage and is equipped with a switch for voltage selection. Verify that voltage selection, power cord and fuse type are compatible with supply voltage prior to connecting to power supply.

6 LED load monitor allows the operator to easily assess operating conditions. Continuous Duty (3 Green LEDs), Intermittent Duty (2 Yellow LEDs), Overload (1 Red LED). If the system is operated in overload for more than 15 seconds, the overload protection system will activate and interrupt power to the motor.

Front panel can be detached (Option)

Front panel can be detached and extended to your control unit with an optional control panel extension cord (Max. 13 ft length)

Incorporates all the functions of the E800

All of the functions of the E800 have been incorporated into the new E800Z Series.