Machine Recycling Discussion and Moderated Newsgroup > Full Machines

> Complete Machines

> Metalworking

> North

> Used

> Beckart environmental wastewater treatment system

Beckart environmental wastewater treatment system

1,000 GALLONS (4.0 CUBIC METERS) PER BATCH

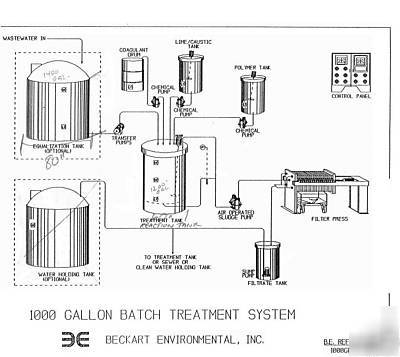

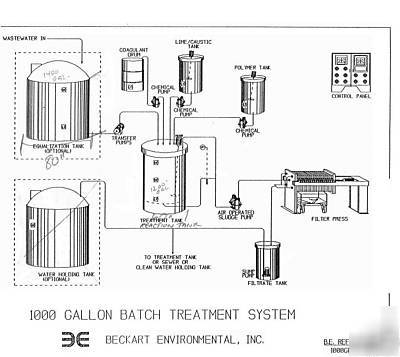

The Beckart Environmental Batch Filter Press Wastewater Treatment System "separates" water-based waste into two disposable waste products. The first product is a clean water stream; the second product is a dry cake consisting of approximately 35% to 50% (by weight) waste solids.

The Beckart Environmental Batch Filter Press Wastewater Treatment System consists of the following: an equalization tank assembly, an equalization tank to chemical treatment tank transfer pumping assembly, a sump sparging assembly, a chemical treatment tank, a coagulant storage and metering assembly, a polymer storage and metering assembly, a pH adjustment chemical storage and metering assembly, a recirculation/sludge transfer pump assembly, a filtrate holding tank assembly, a filtrate submersible pump assembly, an automated electrical control system, and a Beckart Environmental Hy-pack filter press assembly.

The Beckart Environmental Batch Filter Press Wastewater Treatment System operates in the following manner to produce water waste products that can be disposed of in a Publicly Operated Treatment Works (P.O.T.W.) and a solid waste product that in most cases can be disposed of in a landfill. Wastewaters from the process are collected in either a wastewater sump or an equalization tank. The treatment system periodically transfers a fixed volume of waste water into the chemical treatment tank. The treatment system may add potable water to adjust the solids content in the wastewater. Treatment chemicals are automatically added in a sequential fashion to the wastewater to separate selected contaminants from the wastewater. These selected contaminants coalesce into a floc which is separable from the water. After the chemical treatment cycle, the contents of the treatment tank are filtered through the Hy-pack filter press to separate the floc from the water. The filtration process produces a clean water filtrate and a dry cake. Further filtration processing may be performed to remove contaminates not captured in the filter cake. The clean water filtrate may be stored in a clean water holding tank for discharge into the P.O.T.W. or to be reused in the process. Depending on the original contaminants in the wastewater, the processed filtrate water may be used for solids content adjustment of the unprocessed wastewater or for a first time rinse in clean up operations.

This lightly used, fully automatic system was first operational in January, 1996 and taken out of service in early 2000. It is in excellent mechanical and cosmetic condition.

For more information, please call Peter Anderson at (***) 459-1170.