Machine Recycling Discussion and Moderated Newsgroup > Full Machines

> Complete Machines

> Metalworking

> East

> Ryobi 524 gx-f 4-color offset press + aq coater - ryobi

Ryobi 524 gx-f 4-color offset press + aq coater - ryobi

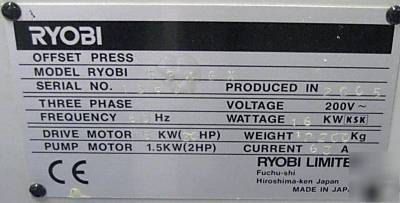

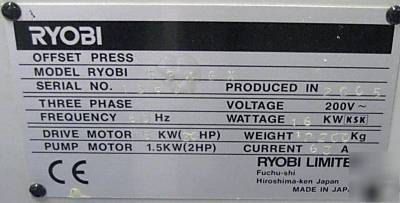

RYOBI 524GX-F 4-Color + AQ Coater (2005 - Current Model)

$365,000 Asking Price - 15m imp

4-Color + AQ Coater - 14x20 - 15,000 sph

Includes: MMT Dryer, Royse Recirculation/Chiller, Roller & Blanket Wash, Paper Size and Impression Cylinder Presets, Extended High-Pile Delivery, PDS-E Scanning Spectro Densitometer & IVS Cip4 Ink Volume Setting Software

* Print & Finishing Solutions (PFS) machine, available for immediate sale. PFS is the RYOBI dealer for Southern California.

A3-Plus Size High-Speed Multi-Color Offset Presses

Advanced Automatic Systems Enhance Efficiency

RYOBI PCS-H Printing Control System (optional on the 522GX)

Almost the entire operation flow from make-ready through printing can be centrally controlled using the touch panel of the RYOBI PCS-H Printing Control System*, greatly shortening make-ready time for changing the paper, cleaning, registration adjustment, color tone adjustment, dampening volume adjustment, and other tasks when switching jobs. The result is superb operating efficiency for a diverse range of small-lot printing.

*On the 522GX, the dampening mechanism, automatic ink roller/blanket cleaning devices, and plate register remote control device are

controlled from the operation panel on the delivery side of the press.

RYOBI Semiautomatic Plate Changer "Semi-RPC"

The RYOBI Semi-RPC allows plates to be changed quickly and accurately. The operator merely sets the plate on the positioning pins and presses the button. A plate bending device is unnecessary, as there is no need to bend the plate's leading or tail edge.

The various automatic cleaning devices*

Automatic blanket cleaning device, Automatic ink roller cleaning device *522GX: option

Pull Side Guide and Impression Pressure Preset Systems*

Simply inputting the paper size and thickness via the RYOBI PCS-H touch panel display automatically sets the impression pressure and pull side guide to the optimal position. The impression pressure preset system includes a program-controlled impression cylinder cleaning function as standard.

*Pull side guide preset and impression pressure preset systems are not available on the 522GX.

Creating the Ideal Workflow for Total Management of Production and Quality

Image Area Calculating Software

[Ink Volume Setter/Ink Volume Setter-CIP4 (PPF)] (option)

Printing Density Control System [RYOBI PDS/RYOBI PDS-E/RYOBI PDS-E Spectro] (option)

MIS Connection Software (for CIP4-JDF) (option)

Management System for Printing Presses [RYOBI Print Job Manager] (option)

Reliable Mechanisms for High-Speed, High-Quality Printing

The satellite type cylinder arrangement consists of a double diameter impression cylinder and double diameter and triple diameter transfer drums. A minimum number of gripper changes and the larger circumference cylinders means less paper curling, important when printing on thick paper.

RYOBI-matic Continuous Dampening System

The RYOBI-matic continuous dampening system assures a uniform dampening supply on the plate surface to reproduce sharp halftone dots, glossy solids and finely detailed text.

The "RYOBI-matic-D" Continuous Dampening System with Hickey Removing Function (option)

This dampening system substantially reduces hickeys on plates by adopting a drive mechanism for the water form roller that creates a rotational speed difference between the water form roller and plate cylinder.

Flexibility to Handle a Wide Range of Jobs

The suction tape feeder board uses a suction belt to securely hold the paper and feed it forward. The feeder board can be quickly and easily set for a wide range of paper sizes and thicknesses.

Compatibility with Many Types of Paper

The 520GX series can print postcards as well as laterally fed envelopes.

Fifth and Sixth Color Printing and an In-Line Coating System Add Value

Fifth and Sixth Color Printing Enhance the Visual Effect of Printed Materials

Fifth- and sixth-color printing units can print custom colors and supplemental colors, including gold, silver, fluorescent and opalescent inks. They easily handle spot-color printing for logos or company names which use specialty inks. These units demonstrate their worth particularly in high-end printing jobs such as pamphlets or art books, which require a strong visual effect with greater detail.

Retractable Coating Unit Design

When the coating system is not being used, the entire coating cylinder and anilox roller can be easily slid upward at the touch of a button to prevent paper marking.

Infrared Dryer and UV Curing Unit

Aqueous coatings are dried by a system that combines heat from an infrared dryer with heated air knives and ambient air knives. The infrared dryer and air knives can be adjusted to provide optimum drying of inks and coatings, delivering ample drying capacity even during high-speed operation. A UV curing unit can be built into the press for applications such as printing jobs that demand quick drying times and glossy printing.

Inter-deck UV Curing Unit (option)

Featuring a cassette-type design, it can be flexibly mounted to suit the type of work, either over the transfer drum between the 2nd and 3rd or 4th and 5th units, or over the coating impression cylinder of the 524GX and 526GX, providing space-savings as there is no need to expand the press.

Fully Automatic Convertible Perfecting Device Boosts Productivity

Fully Automatic Convertible Perfecting Device

Switching between straight printing and perfecting can be performed remotely from the delivery side via the RYOBI PCS-H. The operator simply inputs the paper size and selects a printing mode from the touch panel display.

With Convertible Perfecting Device

520 x 375 mm (20.47" x 14.76")

Straight: 100 x 105 mm (3.94" x 4.13")

Perfecting: 100 x 150 mm (3.94" x 5.91")

505 x 350 mm (19.88" x 13.78")

Straight: 0.04-0.6 mm (0.0016"-0.024")

Perfecting: 0.04-0.4 mm (0.0016"-0.016")

510 x 400 mm (20.08" x 15.75")

[positioning pin pitch: 425 mm (16.73")]

Semi-high pile: 700 mm (27.56")

Design and specifications are subject to change without notice.

The local conditions, ink, stock, and printing plate types, and printing quality required will affect the max. printing speed.