Machine Recycling Discussion and Moderated Newsgroup > Full Machines

> Complete Machines

> Agricultural

> West

> New

> Lab vertical planetary ball mill 4 station gear drive

Lab vertical planetary ball mill 4 station gear drive

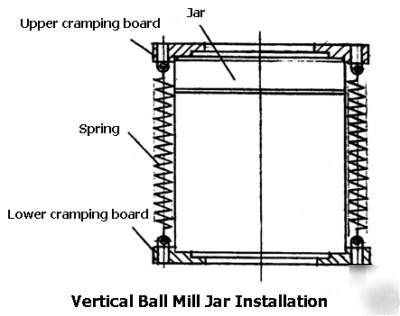

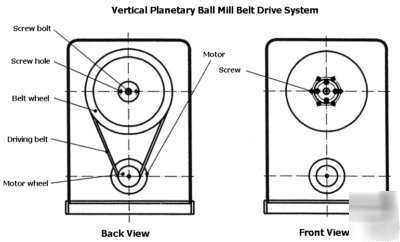

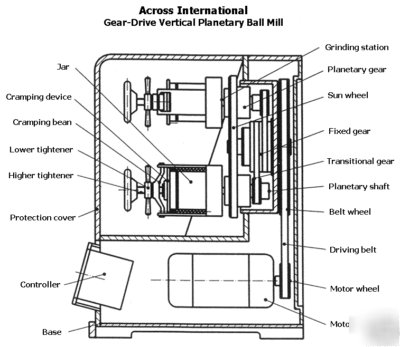

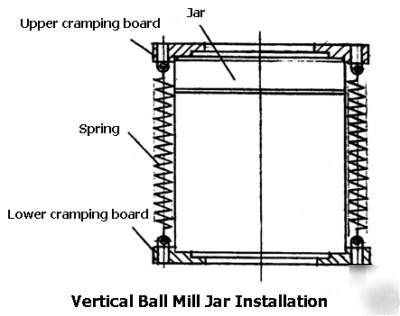

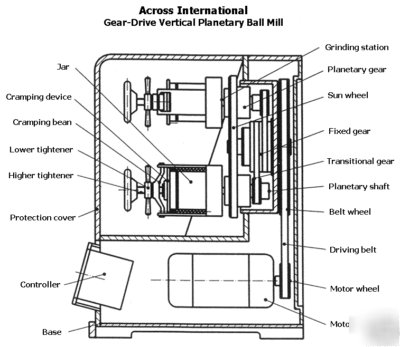

This listing is for a brand new HQ-N04 (0.4L) gear-drive vertical planetary ball mill only, grinding jars and balls are sold separately. Vertical planetary ball mills have 4 ball milling jars installed vertically on a vertical sun wheel. When the sun wheel rotates, the ball milling jars will counter-rotate around their central shaft. Because the ball milling jars have no fixed bases while rotating, the milling balls, with two centrifugal forces caused by the rotation of the sun wheel and the jars, and the gravity, have random movements to cause variable and different grinding forces. When the machine runs at a high speed, the milling balls will obtain very strong impact capacity to shock and grind materials, greatly increase grinding effect and efficiency.

HQ-N series vertical planetary ball mills are the necessary equipments for mixing, fine grinding, small sample preparing, new product development and small volume high-tech material production. This product is compact with complete functionality, high efficiency and low noise. It is the ideal tool to acquire research samples for research institutes, universities as well as enterprise laboratories (can process four samples in one experiment). When used with vacuum ball grinding jars, it can grind samples in vacuum environment. These mills can be used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection, etc.

We also have the HQ-N4 (4L) four liters Vertical Planetary Ball Mill for $6,990. Please contact us for questions.

Can be equipped with 50ml vacuum ball milling tanks

Can be equipped with 50 500ml vacuum ball milling tanks

* The ball milling jars are installed vertically without a fixed base while rotating, jar walls are used as milling faces to greatly increase milling efficiency.

* Step-less speed regulation. Ideal rotational speed can be selected according to test results.

* Elegant appearance, well-designed structure, easy operation, high reliability, safe and low noise.

* Operation Mode: Two or four milling jars working togethe

* Power input: 220V - 240V (Single-phase) 50/60Hz

* Maximum Loading Capacity: 2/3 of the capacity of milling jar

* Feeding Granularity: Soil material 10mm, other materials 3mm

* Final Granularity: Minimum 0.1um

* Rotation Speed: 0.4L: 0 600rpm; 4L: 0 530rpm

* Maximum Continuous Operating Time (full-load): 48 hours

Jar price including grinding balls. (Size of balls available: 2, 3, 6 10 15 20)

1. Standard jars and balls configuration: (unless otherwise specified by user)

Mixed sizes of stainless steel balls for stainless steel jars

Mixed sizes of ceramic balls for ceramic jars

Mixed sizes of Zirconium Oxide balls for Zirconium Oxide jars

Mixed sizes of agate balls (or Zirconium Oxide balls) for all other jars

2. Except for stainless steel, all other jars must use stainless steel cover when used in a vacuum environment.

3. Vacuum jars or cover must be operated with a pump. (Not included)