Machine Recycling Discussion and Moderated Newsgroup > Components

> Wheels and Bearings

> East

> Used

> 15" dia. 80" l supertec G38P-200CII od grinder, auto in

15" dia. 80" l supertec G38P-200CII od grinder, auto in

15" Dia. 80" L Supertec G38P-200CII OD GRINDER, Auto In

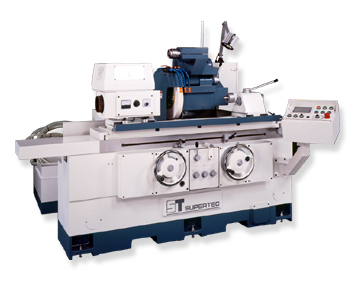

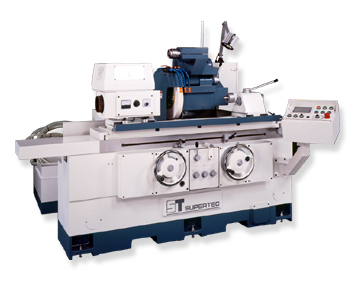

15" Dia. 80" Length Supertec G38P-200CII OD GRINDER, Auto Infeed w/Mitsubishi PLC Control

15" x 80" MODEL G38P-200CII w/Automatic Infeed

NOTE: PHOTO MAY BE OF A DIFFERENT SIZE MACHINE

- Heavily ribbed box-type base is made of Meehanite castings,

providing excellent rigidity to ensure machine stability.

giving variable spindle speeds ranging from 30-350RPM.

Workhead swivels 90 CCW to 90 CW for various grinding operations.

- A dual oil seal and cover prevents coolant seepage into the workhead.

a cast body, the hardened nitralloy steel sleeve is designed to

class 7 (ABEC) bearings incorporated with 7 1/2 HP spindle motor

motor. Smooth movement of the wheelhead delivers longer way life

with superior positioning accuracy and repeatability.

- A special upper slide design adds 7 (180mm) in total wheelhead

travel and increases grinding capacity.

- Rigid table with box-type structure travels on a cushion of oil

with no metal-to-metal contact.Table is fully supported in the full

- Mitsubishi PLC control uses a menu-driven LCD touch screen - it

is easy to learn and easy to set-up. Simply fill in the blanks to set

the total grinding amount, rough increment, fine increment, spark-

out passes, feeding direction, parking position, and retracting

clearance - then press cycle start to complete an automatic

Max. Load Held Between Centers: 330 lbs

Auto incremental infeed (CII) 0.0001" ~ 0.0999"

Handwheel per division: 0.0002

Handwheel per revolution: 0.08

Diameter x Width x Bore: 16 x 2 x 5

Traverse speed (infi variable): 1.2 ~275 /min

Center taper: MT4 (option MT5, 5C)

Spindle speed (infi variable): 30~350 rpm

Spindle speed:G32P/G38P 12000/18000 rpm or 25000 rpm

Max. grinding bore: 4.33 or 2.17

Max. chucking length: 8 ~12.4

Wheel spindle motor: 7.5HP(4P)

Internal grinding motor: 2HP(2P)

Packing dimension: 203 x90 x79 (L x W x H)

- Diamond dresser(fixed on table)

COOLANT SYSTEMS (upgrades from the standard coolant system)

- Coolant system w/mag. separator & paper filter(60L/min,140L)

- Coolant system w/mag. separator (40L/min,108L)

- Coolant system w/paper filter (60L/min,140L)

- 3-Jaw scroll chuck (6") (order with 6 back plate)

- 3-Jaw scroll chuck (8") (order with 8 back plate)

- 4-Jaw independent chuck (8") (order with 8 back plate)

- 4-Jaw independent chuck (6") (order with 6 back plate)

- Royal air-operated 5C collet closer (requires air valve)

- Kit w/hand-operated valve for air 5C

- Kit w/foot-operated valve for air 5C

- Lyndex 5C collets (various sets from 3/64 to 1-1/8 )

- Overhead parallel dresser with auto compensation

- Internal grinding attachment (12000/18000 rpm)

- Internal grinding attachment (25000 rpm)

- Chuck for ID attachment (Arbor type, ER-16)

- Shoulder grinding attachment

- 2-Point steady rest (various sizes)

- 3-Point steady rest (various sizes)

- Two axis (X & Z axis) digital readouts

- One axis (wheelhead) digital readouts

**The D.R.O. display has resolution selections of 0.0002

or 0.0005 for Z-axis, & 0.00002 , 0.00005 , 0.0001 , or 0.0005

ADDITIONAL TOOLING & ACCESSORIES:

- 0.000050 Diameter Micro-infeed attachment

- Hydraulic tailstock w/foot pedal

- MT5 Taper on workhead & tailstock