Machine Recycling Discussion and Moderated Newsgroup > Components

> Structural Parts

> West

> Used

> Wolff hydraulic tree shear for tractor 3 point, loader

Wolff hydraulic tree shear for tractor 3 point, loader

New 2010 Wolff Series IV Hydraulic Tree Shear.

This shear comes complete with a hitch that will fit:

Front End Loaders that use four 1" dia. pins,

The top column also uses 1" pin for 3-point top link. The width of lower brackets can be adjusted to fit your 4-pin front end loaders.

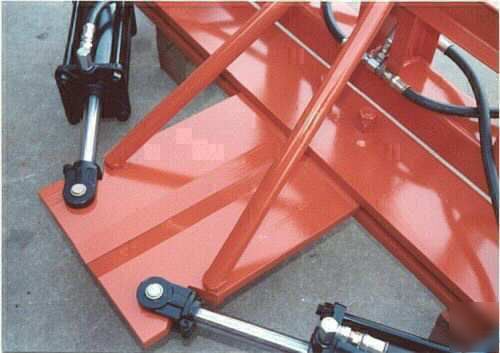

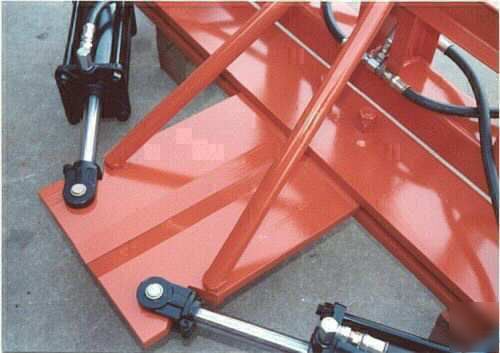

Shear is supplied with CHIEF 5" hydraulic cylinders, 2" rods, rated at 3000 psi, with heavy rod clevis, and high pressure hydraulic hoses. Cylinders shown in some photos are not current version.

If you need an adapter, price for adapters will vary, depending on what you need.

Depending on hydraulic pressure of tractor, and type of tree, it will cut up to 13" diameter tree in one cut. It can also be used to pull brush clumps, small trees, and old fence post out of the ground, by clamping or partially cutting, then lifting shear. It is a great tool to clear unwanted trees and brush from pastures and building sites. It is designed to cut trees near the ground, and not designed to swivel and cut overhead. I build a different machine for that purpose which works very well that is called a "Limb Clipper". Neither unit is complicated by tilt cylinders, electrical switches, or wiring. This is a very basic, strong machine that is built to get the job done without a lot of expense or trouble. The shear alone weighs approximately 800 lbs., according to trucking companies. With a little care, blades should not need sharpened or replaced for a very long time. Rocks won't bother it. Steel "T" post will.

For helpful shear hints, go to http:// /id6.html.

Blades are 1" thick "plow steel". The blades are "milled", not torched. This prevents cracking, caused by torch cuts. All holes in unit are "drilled", not flame cut. All material going into this implement is machined (sawed, drilled, milled, etc.), not flame or torch cut. Attention has been paid to overall appearance, and is very neat and precise. Jigs and fixtures were used for the manufacture of parts and fabrication of weldments to insure interchangeability of parts from one unit to another. When design changes have been made over the years, attention has been paid to backward compatibility with the earlier units. Sensible manufacturing and engineering principles have been followed to give you a good product. This unit will hold it's value for many years in the market.

I have spent my entire working years since 1978 in Engineering, Product Design, and Manufacturing Engineering, also several years in Machining, working for several major manufacturers within an hours drive from here. I grew up in farming, went to technical school, went to the city, and now have returned to the farm to do the things that I enjoy. I am always looking for a better way to do things.

Blades on the current model shear will fit all the earlier versions as well. I can supply parts for any of my earlier models.

For more in depth information, go to http:// /id1.html or call me at (***)-285-6379. Sometimes I'm in the middle of something and can't hear or get to the phone. Feel free to call me from 7 a.m. to 10 p.m. Central Standard Time, seven days a week. Also, if you need to drive down here from who knows where, and need to load in the middle of the night, I can do that. It just needs to be scheduled. I will work with you.

I am located NNW of Stroud, Oklahoma, less than 15 minutes off of I-44 that runs between Tulsa and Oklahoma City. There are good roads to my place, making hauling easy in any kind of weather.