Machine Recycling Discussion and Moderated Newsgroup > Separate Parts

> Electrical Parts

> North

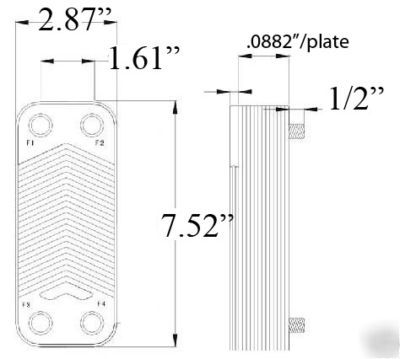

> 10 plate heat exchanger SS304 copper brazed 3/4" mpt

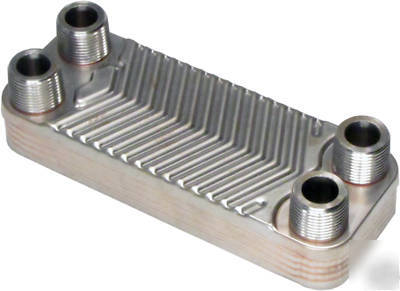

10 plate heat exchanger SS304 copper brazed 3/4" mpt

Lifetime warranty against manufacturer's defects.

Heat Exchanger Characteristics

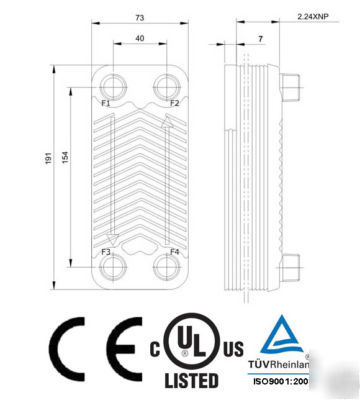

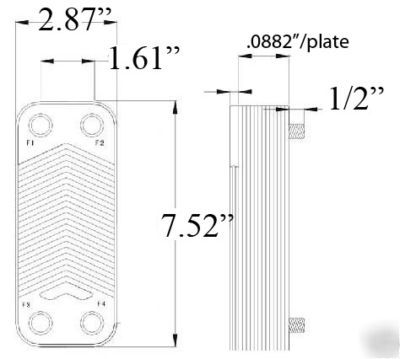

0.012 m /plate (.14 ft /plate)

0.018L/channel (.004756 gal/channel)

-195 C to +220 C (-319 F to 430 F)

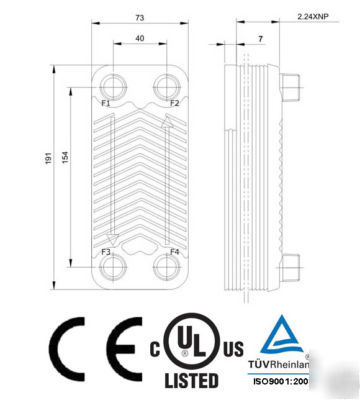

F1-F3 and F2-F4 (see diag above)

SS304 has good general corrosion resistance to a range of organic and in-organic fluids. It will have poor resistance to sulfuric and hydrochloric acids. Crevice corrosion may also occur when chlorides (salts) are present in the fluid. Since chlorides are in all natural sources of water it is best to use distilled water whenever possible. typically, a unit will last about 10 years with regular tap water depending on salt content. Not recommended for use with salt water.

SVO conversions, Heat pump system, household type central air conditioning, after heat recycling, refrigeration equipment, industry cold water machine,cooleroil and so on

Yes - TUVReinland ISO9001:2000

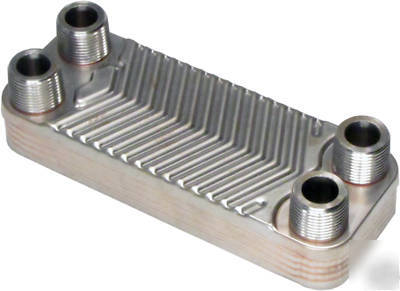

Stainless Steel Copper Brazed Plate Heat Exchangers

Heat transfer occurs when there is a difference in temperature between two mediums. Heat will travel from the hot source to the cold source. The rate at which the heat transfer occurs at is determined by many factors such as the heat conductivity of the two materials andthe difference in temperatures of the two mediums. Convectiuve heat transfer occurs when the materials are moving against each other.

Plate heat exchangers have significantly good heat transfer rates because they use metal plates which have high heat conductivity rates and the plates are extremely thin. The plate heat exchangers also achieve high amounts of heat transfer through convective forces with both working fluids. With large temperature differentials, great amounts of heat transfer can be achieved using a plate heat exchanger.

Corrosion is usually how these units will fail. Use fluids with reasonable pH levels to ensure a long lasting life. Hard water will corrode faster than regular water. (Use distilled if possible; Distilled should never corrode it) Salt water will corrode stainless steel very fast. It is recommended to clean the exchanger often if you are using corrosive fluids. Normal usage (non-corrosive fluids) should expect 10-20 years of life. Fluids containing chlorides will corrode the unit quickly.

This is an extremely popular unit for wood burning furnaces, radiant floor systems, refrigerant systems, straight vegetable oil conversions, beer chilling, air conditioning system and solar water heating systems. It will work for any application in which the desired result is for two fluids (liquid or gas) to exchange heat.

Fluid A passes from the port on the left of the heat exchanger through every other channel created by the plates to the opposite end port on the left of the heat exchanger (looking at it the long way). Fluid B passes from the port on the right through the other channels created by the plates and comes out the other port on the right side. The fluids are essentially touching each other through the plates and heat is transferred from the hot fluid to the cold fluid. (but the fluids do not mix)

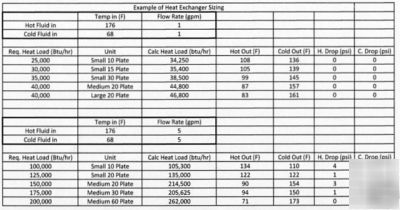

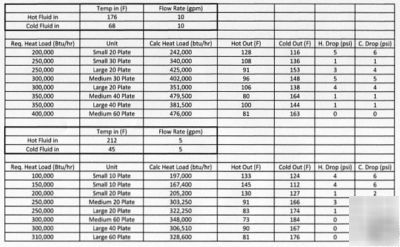

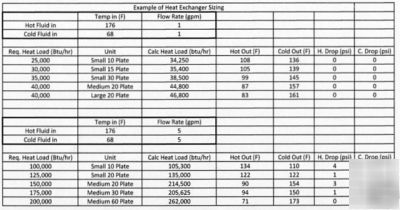

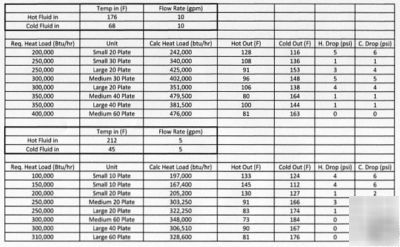

Type of both fluids (water, antifreeze mix, R22?)

Inlet temperature of both fluids

Max pressure drop for both fluids (default is 7 psi if not provided)

Outlet temperature of hot fluid

Outlet temperature of cold fluid

Heat transfer desired (Btu/hour)